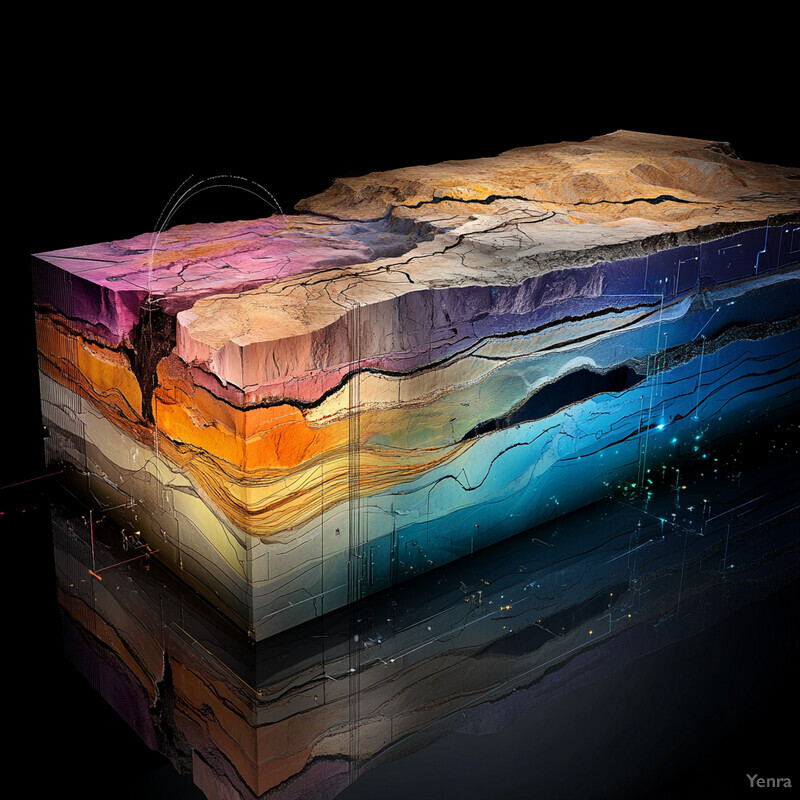

1. Automated Geological Data Integration

AI-driven platforms rapidly integrate diverse geological datasets—including drill logs, maps, seismic surveys, and geochemical assays—into unified models. This holistic data integration enables geologists to see patterns and correlations that were previously hidden in siloed data. By combining data types in real time, AI reduces the turnaround for updating geological interpretations as new information comes in. The result is a more comprehensive subsurface understanding, improving decision-making on where to explore next. Ultimately, automated data integration helps target promising zones more efficiently and minimizes oversight of critical clues.

Modern machine learning systems can ingest enormous volumes of heterogeneous geoscience data and detect subtle signals invisible to humans. For example, a 2024 study applied deep domain adaptation to merge drilling data with geophysical survey data, overcoming the challenges of different scales and methods between datasets. This approach allowed the model to interpret broad geophysical anomalies in light of detailed drill information, improving ore-zone identification across data domains. Such integrated AI analyses have been credited with highlighting mineralization patterns that traditional, single-source interpretations missed. By unifying legacy logs, current sensor readings, and spatial datasets, AI integration provides a richer, more reliable basis for exploration planning.

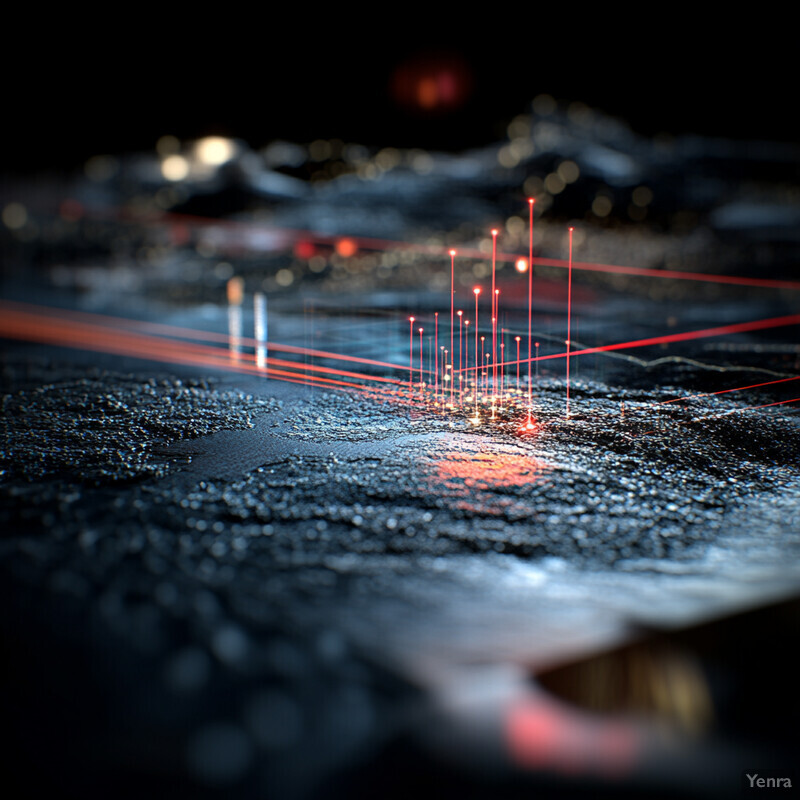

2. Advanced Geophysical Interpretation

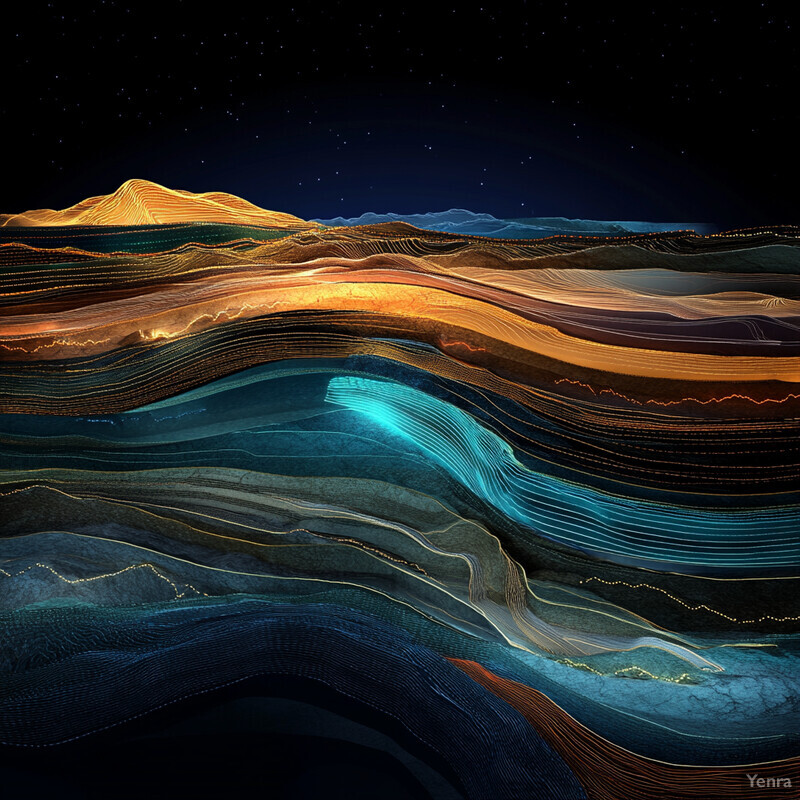

AI is enhancing the interpretation of geophysical survey data (magnetics, gravity, electromagnetic, seismic) by quickly recognizing complex anomaly patterns. Machine learning models can sift through multi-dimensional geophysical datasets to identify subtle features—such as faint magnetic lineaments or weak gravity gradients—that might indicate underlying structure or mineralization. By reducing reliance on purely manual contour analysis, AI-driven tools provide more objective anomaly picks and 3D interpretations. This accelerates the geophysical workflow and improves the accuracy of targeting hidden ore bodies controlled by geological structures.

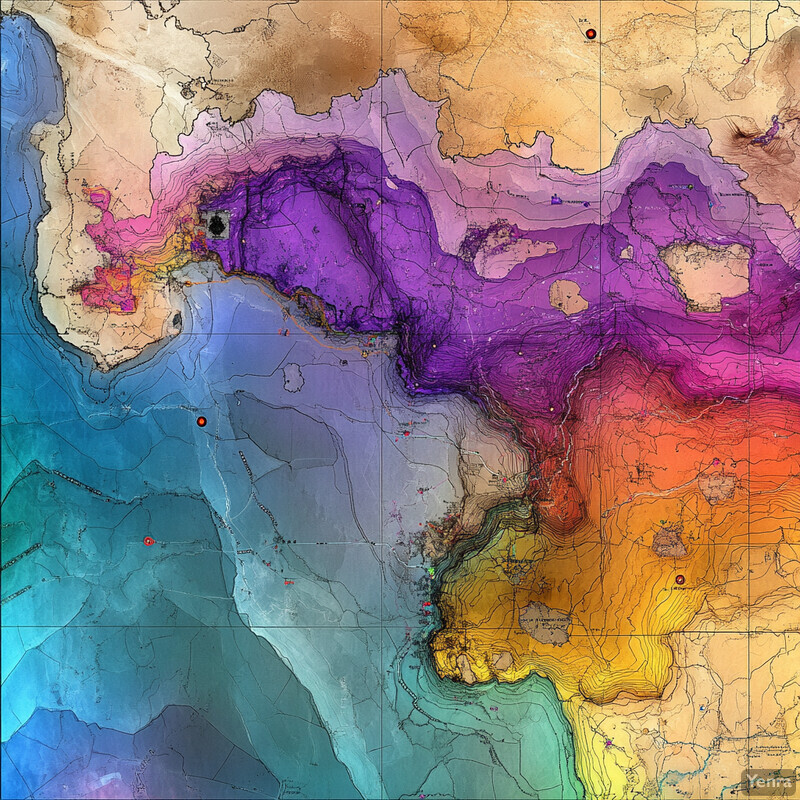

Unsupervised learning techniques have demonstrated success in mapping geological structures from geophysical data. In one 2024 project, researchers combined signal processing and clustering algorithms on regional magnetic and gravity data to automatically delineate the internal faulted architecture of Australia’s Gawler Craton. The AI-derived structural maps were validated against known geology and showed that nearly all significant mineral occurrences lay near the boundaries of the clustered structural domains. By focusing on these AI-identified structural boundaries, the exploration team could significantly reduce the search area for new deposits hosted by faults or shear zones. This example illustrates how AI-driven geophysical interpretation can reveal hidden frameworks and guide explorers to prospective structural traps much faster than traditional methods.

3. Faster Mineral Targeting

By detecting subtle geochemical and geophysical patterns, AI algorithms can generate high-priority exploration targets in a fraction of the time of traditional methods. Machine learning models quickly analyze multivariate exploration data to flag anomalies or combinations of features indicative of mineralization, dramatically accelerating the target-generation phase. This speed allows exploration teams to iterate rapidly—testing targets, integrating new drill results, and refining predictions on the fly. Faster targeting not only reduces the time to discovery but also lowers costs by focusing drilling on the most promising areas earlier in the exploration campaign.

Neural networks have shown the ability to identify drill targets much faster than manual analysis. In a 2023 field trial, geologists used an AI tool to train on historic drill assays and surface data; the trained model produced a detailed gold mineralization probability map in under one minute, a task that normally takes weeks. The AI output highlighted a southwest-dipping high-grade trend that was not obvious from raw data alone, and even suggested new drill orientations to test the model’s prediction. Mining companies are also partnering with tech firms to speed up targeting—Barrick Gold’s use of an AI-guided seismic system reportedly can outline prospective copper zones “up to 100 times faster” than traditional methods (a claim by technology provider Fleet Space). These examples demonstrate substantial reductions in target-generation time, allowing companies to compress the exploration timeline and reach discovery decisions sooner.

4. Predictive Resource Modeling

Deep learning models are increasingly used to predict mineral resources and reserves by learning from the spatial patterns of known deposits. By analyzing large datasets of past discoveries—such as the geometries of ore bodies, host rock characteristics, and geochemical signatures—AI can extrapolate the likelihood and size of undiscovered resources in a region. These models serve as a “digital exploration geologist,” providing probabilistic estimates of resource potential that update with new data. Predictive modeling augments traditional methods by quantifying the confidence in potential resources and guiding where to focus drilling to confirm those predictions.

Machine learning can match or even improve upon traditional geostatistics in resource estimation accuracy. A 2023 comparative study tested a deep neural network against ordinary kriging for grade modeling in a mineral deposit. The results showed the neural network achieved a comparable coefficient of determination (R² ≈ 0.72) to kriging (≈0.75) on held-out data, with similarly low mean squared error. In practice, integrating AI into resource modeling workflows has yielded tangible improvements. For instance, researchers applying a feed-forward neural network to a Chilean copper reserve model found a 21% reduction in estimation error relative to the mine’s conventional model; more advanced models (1D CNN and LSTM) cut error by 37–39%, significantly tightening the precision of the resource predictions. These peer-reviewed cases underscore how data-trained models can provide more precise and data-driven resource estimates, especially when nonlinear relationships or complex mineral distributions are present.

5. Machine Vision in Core Logging

Computer vision technology is transforming drill core logging by automatically identifying minerals, textures, and structures from high-resolution core images. Instead of relying solely on geologists’ visual inspections (which can be slow and subjective), machine vision algorithms consistently analyze each foot of core or each thin-section slide for mineralogical and textural clues. The AI can rapidly classify rock types, detect veins or alteration halos, and digitize these observations into a permanent record. This accelerates the logging process and ensures that subtle features (color changes, grain size variations, micro-fabrics) are captured uniformly. Ultimately, automated core imaging frees geologists to focus on interpretation while improving the objectivity and reproducibility of core logs.

AI-driven image recognition now approaches expert-level accuracy in identifying minerals and rock types from core and thin-section images. In one 2023 experiment, a deep learning model was trained to recognize common rock-forming minerals in microscope images; it achieved an overall 97.6% accuracy in mineral identification, with certain minerals (e.g. quartz, feldspar) correctly identified over 99% of the time. Likewise, convolutional neural networks have been used to classify lithologies directly from core photographs. A recent study reported that a CNN model could distinguish drill core segments by formation with 96.7% accuracy, closely matching human geologists’ classifications. Moreover, the same model predicted mineral content (e.g. silicate vs. carbonate percentages) from the images, and its estimates were as reliable as laboratory X-ray diffraction analyses of the core. These results demonstrate that machine vision can greatly speed up core logging while maintaining high fidelity to traditional analytical results.

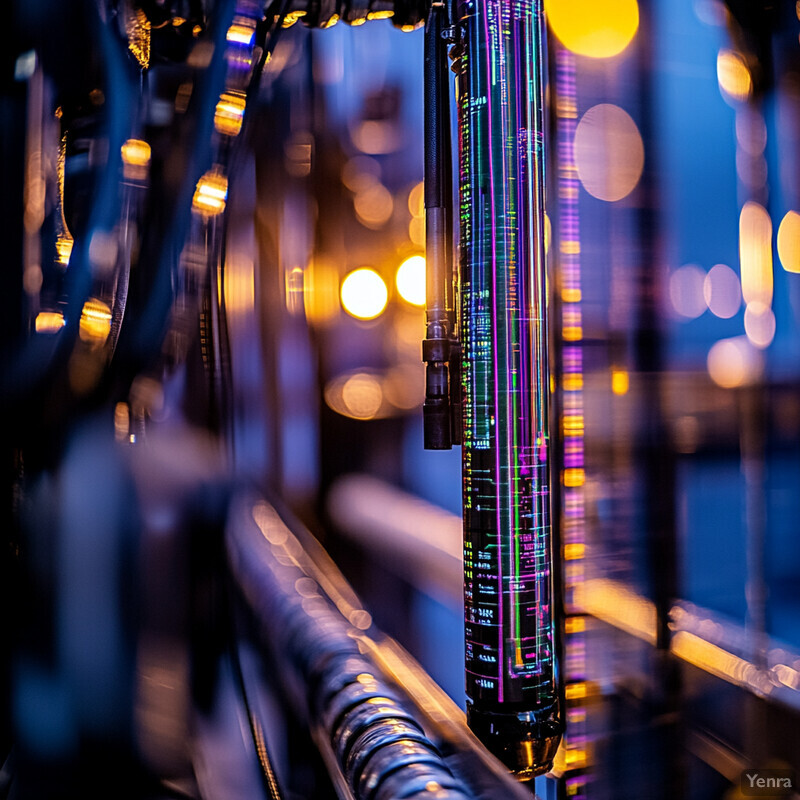

6. Intelligent Drilling Guidance

AI can guide exploration drilling in real time by assimilating sensor data and adjusting drilling parameters or paths on the fly. Traditional drilling follows a pre-set plan, but intelligent systems use feedback (rock hardness, penetration rate, downhole geophysics, etc.) to “steer” the drill toward the most promising geology. This dynamic guidance helps avoid unnecessary drilling in barren rock and ensures drill holes stay within target mineralized zones. In practice, intelligent drilling can mean pausing or redirecting a hole when sensors indicate poor prospects, or drilling deeper when unexpected mineral indications appear. By continually updating the subsurface model as a hole is being drilled, AI guidance maximizes the efficiency of each meter drilled and improves the odds of intersecting economic mineralization.

The oil & gas sector has pioneered AI-driven drilling adjustments that are now inspiring mining applications. For example, in late 2024 Schlumberger introduced an autonomous AI geosteering system that interprets real-time downhole data and automatically adjusts the drill bit trajectory to stay in the “sweet spot” of a reservoir. Instead of a human geologist manually reorienting the well based on intermittent data, the AI continuously integrates measurements (like gamma ray logs and resistivity) and updates the drill path autonomously. In a mining exploration context, similar principles are emerging: AI algorithms can take logging-while-drilling readings (rock type, geochemistry, acoustic feedback) and recommend stopping or deviating a hole if it enters unmineralized ground. Drilling is one of the costliest exploration activities, often consuming 40–50% of project budgets, so even modest efficiency gains are valuable. Early trials indicate that AI-guided drilling can reduce “dead” drilling by immediately reacting to unfavorable signs, thereby allocating meters to more prospective ground and saving substantial costs in failed holes.

7. Enhanced Grade Estimation

AI techniques are improving the accuracy of mineral grade estimates in resource models. Traditional grade interpolation (e.g. kriging) is statistically robust but can struggle with complex, non-linear grade distributions. Machine learning models—trained on drill assay data—can capture subtle relationships between geology and grade, leading to block models that better reflect high-grade shoots and grade variability. Improved grade estimation means companies can forecast mineable reserves with greater confidence and optimize mine plans (cut-off grades, scheduling) on more reliable data. By reducing estimation error and bias, these AI-enhanced models support more efficient resource extraction and investment decisions.

Deep learning models have demonstrated significant gains in grade prediction performance. In one case study at a Chilean copper deposit, researchers trained neural networks to estimate ore grades as part of long-term mine planning. The AI models substantially outperformed the conventional estimates: a simple neural net reduced the mean squared error of grade predictions by 21%, and more advanced 1D CNN and LSTM models achieved 37% and 39% error reductions, respectively, compared to the standard geostatistical approach. Similarly, a 2024 comparative study found that a 3D convolutional neural network achieved grade estimation accuracy on par with industry-standard kriging while better capturing complex mineralization trends. These improvements can translate into millions of dollars in project value. By lowering the uncertainty in grade-tonnage curves and avoiding under- or overestimating ore quality, AI-enhanced grade models allow mine planners to design more optimal pits and schedules. Overall, the integration of ML-based grade estimation is yielding more precise resource evaluations and higher confidence in reported reserves.

8. Geochemical Anomaly Detection

AI models excel at sifting through large geochemical datasets to flag subtle geochemical anomalies that might indicate hidden mineralization. Traditional geochem exploration often relies on threshold-based maps of single elements or simple ratios. In contrast, machine learning can analyze multi-element patterns simultaneously, identifying combinations of trace elements or element ratios that together suggest an ore-forming process. By employing techniques like anomaly detection algorithms or clustering, AI finds geochemical “signals” in noisy regional data that a human might overlook. This leads to more informed geochemical targeting—areas with faint but significant chemical halos can be identified for follow-up, even if no single element is highly anomalous by itself.

Researchers have applied data-mining algorithms to improve geochemical anomaly interpretation. A 2023 study combined principal component analysis (PCA) with an Apriori association rule algorithm to automatically find meaningful element groupings in a geochemical survey. In a Zn-Pb exploration context, the AI technique confirmed that lead, zinc, and barium form a related suite, highlighting anomalies where those elements jointly peaked—areas likely reflecting hidden Pb-Zn mineralization. This AI-driven approach went beyond what PCA alone provided, validating that the second principal component (Pb-Zn-Ba association) was clearly linked to ore-bearing strata. Other projects have used unsupervised clustering on regional stream sediment data to isolate multi-element anomaly clusters corresponding to known deposits. By detecting these subtle geochemical patterns and combinations, AI tools increase the chances of discovering mineralization that lacks a strong single-element signature.

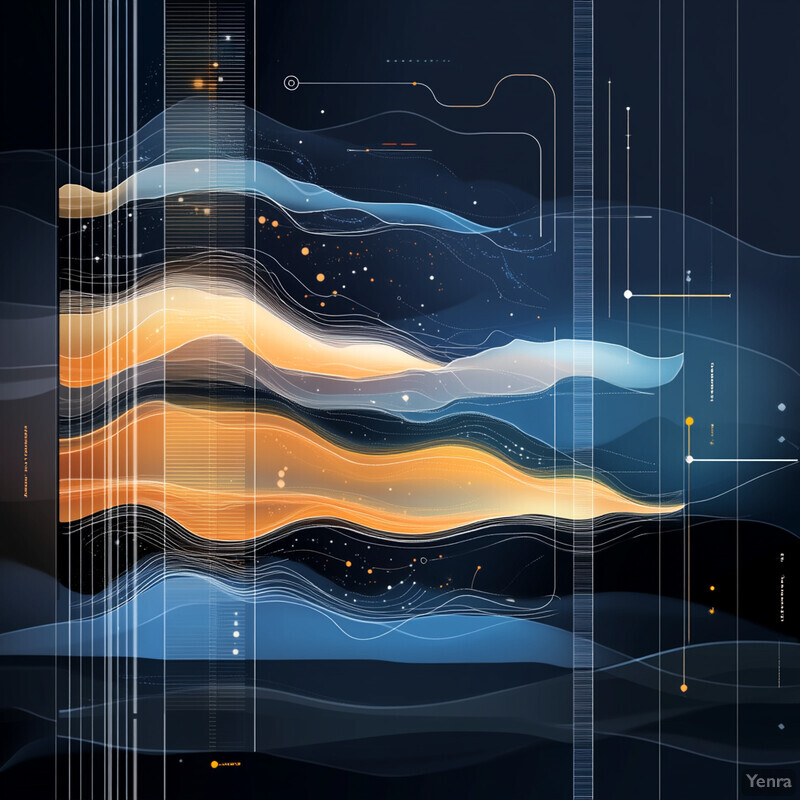

9. Seismic Attribute Extraction

AI is streamlining the extraction of meaningful attributes from seismic data, a practice crucial for both petroleum and mineral exploration in covered terrains. Instead of manually computing multiple seismic attributes (e.g. reflection strength, phase, frequency content) and then interpreting them, neural networks can learn to directly output features of interest—such as likely lithology changes or fault indicators—from raw seismic input. This not only speeds up the processing (especially for large 3D seismic volumes) but can reveal complex attribute combinations that correlate with geology. By automating attribute generation and pattern recognition, AI reduces human bias and accelerates the interpretation of seismic surveys for exploration targeting.

A recent study demonstrated that a deep learning approach can replace numerous traditional seismic attribute calculations. Researchers trained a U-Net convolutional neural network (with ~31 million parameters) on a benchmark 3D seismic dataset to predict various seismic attributes from the raw seismic traces. The trained model produced key attributes (e.g. instantaneous phase, amplitude variance, etc.) with low prediction error, effectively recreating the attribute volumes without explicit conventional computations. This indicates the CNN learned the complex transformations necessary to derive geologically useful attributes. In practical terms, such a model can infer attributes like “seismic facies” or “fracture density” in one pass, significantly speeding up interpretation. Similarly, other researchers have used deep networks to identify faults in seismic images—one 2024 method using an LSTM-based neural net automatically highlighted fault planes across a 3D seismic cube, showing higher continuity and accuracy than manual fault picks. These examples illustrate how AI-driven attribute extraction makes seismic interpretation faster and more objective, aiding exploration in complex subsurface settings.

10. Improved Geological Domain Modeling

AI assists geologists in defining geological domains (rock units, ore zones, stratigraphic layers) more objectively by clustering and classifying data. In traditional modeling, drawing domain boundaries can be subjective, relying on expert judgement of drill data and maps. Machine learning can analyze multivariate geological data—such as assays, alteration indicators, or geophysical logs—to group similar rock zones without bias. These data-driven domains often capture subtle variations that manual interpretation might miss. The result is more consistent 3D geological models, where each domain is statistically distinct and thus better suited for subsequent resource estimation or mine planning. Essentially, AI provides a reproducible way to partition the geology into meaningful units based on the inherent data patterns.

Unsupervised learning methods like k-means clustering and self-organizing maps have been successfully used to improve domain delineation. In one 2025 example, geologists applied k-means clustering to multispectral satellite imagery of a remote exploration tenement to automatically classify surface lithologies. The resulting cluster map revealed far more lithological detail than the existing regional geologic map, highlighting variations in surface composition at high spatial resolution. While the clusters initially had no names, they corresponded to distinct spectral signatures that geologists could then interpret (e.g. differentiating various volcanic units). By focusing field mapping on differences flagged by the AI, the team refined their geological domains before even stepping on site. Similarly, other projects have clustered downhole geochemical and geophysical logs to divide drill data into statistically distinct lithology groups, which often align with rock types or alteration zones identified later by experts. These data-driven domain models reduce human bias and ensure that subsequent resource modeling honors real geological variability present in the data.

11. Rapid Hyperspectral Image Analysis

Hyperspectral imaging of cores and outcrops provides extremely rich mineralogical data, but AI is making it feasible to utilize this data quickly in exploration. Each hyperspectral scan can contain hundreds of wavelength channels for every pixel, resulting in huge datasets that are slow to interpret manually. AI algorithms can automate the calibration, mineral identification, and visualization of hyperspectral results in near-real time. This means geologists can get mineral maps of drill core or field exposures immediately after scanning, allowing on-site decisions about where to drill next or which samples to assay. Rapid hyperspectral analysis ensures that this high-resolution mineralogical information is integrated into exploration models while it’s most useful, rather than weeks or months later.

A 2024 study by a German-Moroccan team demonstrated real-time processing of large hyperspectral drill core datasets. They developed an open-source workflow and web platform to handle over 6.4 km of drill core scans, amounting to more than 1 terabyte of hyperspectral data, from projects in Ireland and Germany. The AI-driven pipeline performed on-site correction, mineral classification, and visualization of the core mineralogy essentially as the core was scanned. Critically, the researchers found that if hyperspectral results are obtained during an active drilling campaign (rather than post-campaign), geologists can immediately validate anomalies and adjust drilling—deciding to extend a hole or terminate early based on mineral indicators detected in the core. This timely integration led to better-informed decisions on sample selection and drill-hole planning in their case studies. The work underscores that processing hyperspectral data in real time, enabled by AI, unlocks its full value for exploration by feeding ultra-detailed mineralogy into the decision cycle without delay.

12. Optimized Resource Estimation Workflows

AI tools are being embedded into traditional mine planning and resource modeling software, streamlining each step from data import to resource classification. By automating tedious or complex tasks (such as trend analysis, variography, or grade interpolation tuning), these AI integrations allow geologists and engineers to generate resource estimates faster and with fewer manual adjustments. Workflows that once required switching between multiple software or iterative human refinements can now be executed in a more automated, cohesive process. Optimized workflows mean that teams can update models more frequently as new data arrives, maintain more dynamic “live” resource models, and reduce the turnaround time for mine planning scenarios or feasibility studies.

Major mining software platforms have begun incorporating machine learning modules to enhance workflow efficiency. For instance, Micromine introduced an AI-powered “Grade Copilot” in 2023 that plugs into its 3D modeling environment. This tool uses neural networks to perform grade estimation and pattern recognition directly within the modeling software. In a case study, geologists using Grade Copilot were able to generate a fully quantified block model from raw drillhole data in hours instead of days, with the AI autonomously handling domain partitioning and grade interpolation steps. The output model closely matched the results of a manual resource estimate but required far less human input. Similarly, companies like Seequent and Datamine have announced AI integration roadmaps for their flagship products, aiming to cut down manual data prep and accelerate convergence of resource models (e.g., automatic outlier detection, smarter default parameters for estimators). Early industry reports suggest that incorporating AI into resource workflows can reduce the total modeling time by 30% or more, while also improving consistency between different modelers’ results. These efficiencies free up experts to focus on interpreting the model and evaluating project economics rather than wrangling data and tweaking parameters.

13. Drillhole Spacing Optimization

AI algorithms can help determine the optimal spacing and orientation of drill holes to delineate a mineral resource efficiently. Instead of relying solely on uniform grids or manual judgment for infill drilling, intelligent systems evaluate the current geological model and identify where additional drill data would most reduce uncertainty. By simulating many drilling scenarios, AI can recommend a drilling pattern that achieves the desired resource confidence (for example, upgrading from inferred to indicated category) with the fewest holes. This optimization minimizes redundant drilling in over-sampled areas and focuses new drilling where it yields the maximum information gain. The result is a more cost-effective drilling campaign that still meets the geological confidence requirements for resource estimation.

Recent work in exploration planning uses AI agents and Bayesian decision theory to optimize drill programs under uncertainty. In one 2024 study, researchers from KoBold Metals and Stanford developed an “intelligent prospector” system that plans drillhole locations by considering multiple geological hypotheses and their uncertainties. Tested on a sediment-hosted copper prospect, the AI agent dynamically selected drilling targets that maximally reduced uncertainty about the orebody. Notably, the algorithm identified an ultra high-grade copper zone in Zambia with fewer drills than a traditional approach by steering away from areas that data proved unpromising and refocusing on more probable zones early on. This optimal planning saved significant meters of drilling that would have been wasted testing now-disproven geological models. More generally, simulations published in 2023 indicate that machine learning can cut required infill drillholes by ~20–30% for a given resource confidence by smart positioning (especially in complex deposits) – a substantial cost reduction. These findings show that AI can guide explorers to “drill smarter, not just harder,” achieving classification goals with minimal drilling expenditure.

14. Real-time Sensor Data Analysis

AI systems can continuously analyze streaming data from drilling sensors and downhole tools to update geological models in real time. Modern exploration drills are often equipped with measurement-while-drilling (MWD) sensors (recording properties like gamma radiation, acoustic velocity, torque, etc.) and bring up rock chips that can be scanned on-site. Instead of waiting for a hole to be completed and assays returned, AI can interpret these sensor signals on the fly, inferring rock type and mineralization indicators as drilling progresses. This live analysis means decisions such as “keep drilling vs. stop” or “alter direction” can be made immediately based on data. Real-time data integration also ensures that each new piece of information (even from a single meter of drilling) refines the exploration model without delay, leading to a highly adaptive exploration strategy.

In 2023, a study showcased how machine learning can derive geological information from real-time drill data. Researchers applied regression ML algorithms (linear regression, random forests, support vector machines, etc.) to MWD data from blast holes to predict various geophysical and lithological properties of the rock being drilled. The models were able to estimate attributes like rock density, natural gamma count, and even proxy mineral indicators directly from the drilling parameters and sensor readings. Decision tree-based models (including random forest and gradient boosting) performed best, successfully mapping patterns in MWD signals to specific geological features encountered in an open-pit mine’s boreholes. While some accuracy limitations remain (the method is inherently constrained by how diagnostic the sensor data are of geology), this approach proved it’s feasible to do “real-time logging.” In practical terms, it means an AI could signal, for example, a drop in predicted ore grade within meters of a sensor reading, prompting geologists to adjust the drilling plan instantly. Companies are beginning to deploy such systems so that their geological models update continuously—during drilling—rather than only after lengthy laboratory assays, thereby greatly accelerating the exploration feedback loop.

15. Reduced Exploratory Risk

AI brings a more data-driven approach to exploration, which helps reduce the risk of drilling dry holes or pursuing false targets. By analyzing historical data and real-time inputs, AI can better rank target areas by their discovery potential, so companies focus their budgets on the most promising prospects. This improves the “hit rate” of exploration—finding more viable deposits per number of targets tested. Reducing risk is crucial in exploration, where traditionally only a tiny fraction of prospects become mines. With AI’s ability to integrate diverse evidence and learn from past successes/failures, exploration programs become less of a blind gamble and more of a calculated, model-guided endeavor.

The mining industry’s base success rate in exploration is very low – only about 0.1% (1 in 1000) of early-stage mineral prospects ever develop into a profitable mine. AI aims to improve those odds. According to a 2024 industry analysis, data-driven targeting (machine learning on geological and remote sensing data) has increased the likelihood of discovery by up to 20% relative to conventional methods. In practical terms, this can mean perhaps 1.2 successes out of 1000 prospects instead of 1 – a modest but material improvement given the high stakes. Companies like Goldspot and KoBold have reported that AI-based target selection helped them avoid unprospective areas and led to several new mineral discoveries that were missed by traditional approaches. Furthermore, by quantifying uncertainties and providing probabilistic targets, AI allows management to make more informed decisions about which projects to fund or drop. The overall impact is a more efficient use of exploration capital: fewer dry holes, earlier exit from doomed projects, and a greater focus on targets with strong multi-data support, thereby lowering the risk profile of exploration portfolios.

16. Uncertainty Quantification

AI methods enable quantification and visualization of uncertainty in resource models, which is critical for decision-making. Unlike a single deterministic estimate, AI can produce a range or distribution of possible outcomes (e.g. grade-tonnage curves) and associated probabilities. Techniques such as ensemble learning, Bayesian neural networks, or Monte Carlo simulations with surrogate models allow assessment of both aleatoric uncertainty (data noise) and epistemic uncertainty (model ignorance). By highlighting where the model is confident vs. uncertain, AI-driven uncertainty analysis guides where additional data (like more drilling) would most improve the model. This leads to more transparent resource assessments—with “error bars” clearly stated—and helps management balance risk vs. reward in project development.

Researchers are actively incorporating uncertainty modeling into AI exploration tools. A 2024 paper by Caers and colleagues introduced an AI agent that explicitly accounts for uncertainty by considering multiple plausible geologic scenarios when planning drillholes. The system uses a prior distribution of possible orebody configurations and updates it as data comes in, effectively performing Bayesian learning. Notably, the AI could detect early on if all the human-formulated geological hypotheses were likely wrong, prompting geologists to revise their conceptual model rather than continue drilling under false assumptions. This saved considerable wasted drilling. In resource estimation, new AI approaches like Bayesian neural networks provide not just a grade estimate for each block but also a credibility interval (e.g. ± one standard deviation) for that estimate. For example, a 2023 study applied Monte Carlo dropout in a grade-prediction neural net to generate thousands of realizations; the variability among realizations mapped out the spatial uncertainty in grade, highlighting areas of high uncertainty that would benefit from infill drilling. By integrating such probabilistic outputs into their models, companies can clearly see which parts of a resource are well-known vs. speculative, leading to smarter risk management (like targeting drilling to high-variance zones or adjusting mine plans to avoid overly uncertain regions).

17. Integration of Legacy Data

AI is unlocking value from decades’ worth of historical exploration data—old maps, reports, drill logs, and surveys—by converting them into usable digital form and extracting insights. Much legacy data exists on paper or in disparate formats, often underutilized due to the effort required to synthesize it. Machine learning (especially natural language processing and computer vision) can rapidly scan and digitize these archives, geo-reference historical maps, and even interpret old drilling results or handwritten field notes. By doing so, AI brings “new life” to past data, allowing modern exploration teams to build upon all previous work in an area without re-drilling or re-surveying. This not only saves time and cost but can also reveal missed opportunities where historical programs stopped short of a discovery.

A striking example in 2025 showed how AI agents combed through historical exploration archives to find overlooked prospects. Startup RadiXplore deployed a multi-agent AI system to analyze millions of pages of old exploration reports in Western Australia’s public database (WAMEX). The AI identified numerous cases of “near misses” – projects from decades past where drilling was terminated early due to technical problems or budget cuts, even though the geology was promising. In these instances, the old reports (drilled intervals, assays, comments) were often unstructured, but the AI agents parsed them to flag targets that were never fully tested. Thanks to this AI-driven review, companies revisited at least one of these historically written-off prospects and discovered significant mineralization by drilling deeper than the 1970s-era attempt. More generally, mining teams are using NLP algorithms to extract data from scanned exploration PDFs and georeference old geologic maps; the U.S. Geological Survey, for example, has begun partnering with tech firms to digitize its vast library of mining records via AI. Such efforts demonstrate that integrating legacy data with modern datasets gives explorers a more complete picture of a region’s geology and prevents redundant work.

18. Structural Geology Analysis

Identifying structural features like faults, folds, and shear zones is essential in exploration, and AI is making this process faster and more consistent. Machine learning can be trained to recognize linear or curvilinear patterns in geological datasets (e.g. geophysical grids, topography, drill data) that indicate structures. By processing huge areas or volumes of data objectively, AI ensures no subtle lineament or inflection is overlooked. The outcome is a detailed structural framework that guides exploration by highlighting likely conduits or traps for mineralization (since many ore deposits are structurally controlled). Integrating an AI-derived structural interpretation early in exploration helps target efforts toward structurally favorable areas with greater precision.

AI-based structural analysis has been proven on both regional and local scales. In the example of the Gawler Craton study (South Australia), unsupervised clustering of gravity and magnetic data automatically mapped crustal faults and boundaries, effectively illuminating hidden fault networks under cover. The clustered output corresponded well with known major faults from geological mapping and importantly revealed additional lineaments in areas with sparse outcrop. The significance for exploration was clear: the study found that all significant mineral deposits in the area lay near the AI-defined cluster boundaries (i.e., major structural discontinuities), reinforcing that mapping those structures can narrow down search areas dramatically. At the deposit scale, computer vision techniques have been applied to drill-core imagery and mine face photographs to pick out fracture traces and veins—one 2023 implementation used a neural network to detect and trace faults in underground mine imagery with over 90% agreement to expert mapping (speeding up mapping of rock bolt hazard areas). Whether from remote sensing or core scans, AI provides geologists with consistent structural interpretations, which are crucial for refining exploration targets along likely fluid pathways and trap sites.

19. Automated Classification of Rock Types

AI is improving the speed and consistency of lithology identification from various exploration datasets. Whether it’s classifying rock chips from a drill rig, recognizing rock types in core photos, or analyzing petrographic microscope images, machine learning can rapidly assign rock type labels based on patterns it has learned. This reduces subjective differences between geologists and ensures that the same criteria are applied across all samples. Automation is especially valuable when dealing with thousands of samples or continuous sensor data (like downhole hyperspectral logs). By quickly turning raw observations into classified rock types, AI-driven lithology logging helps maintain up-to-date geological models and frees geologists to concentrate on higher-level interpretation.

Automated rock type classification has reached high accuracy levels. As mentioned, a 2024 deep learning model attained 96.7% accuracy in sorting drill core segments into the correct formation (rock unit) classes purely from core photographs. Another study focusing on cuttings images (simulating real-time drill chip analysis) reported that a trained CNN could classify rock types (sandstone vs. shale vs. limestone, etc.) with over 90% accuracy in a matter of milliseconds per image, far faster than manual logging. These AI models use features like color, texture, grain size, and mineral content gleaned from the images to make their determinations. Beyond imagery, machine learning has been applied to geochemical signatures for rock classification: for instance, unsupervised clustering of multi-element data has successfully separated rock types in greenfield exploration, revealing lithologies not distinguished in initial field logs. Importantly, AI classification provides consistency—if the training data are well-curated, every foot of core or every cutting gets classified by the same standards, eliminating human fatigue or bias factors. Mining companies are beginning to deploy such systems at the rig site (e.g., camera systems on chip collectors or core scanning units) so that a first-pass lithology log is generated in real time, which geologists then verify and refine.

20. Continuous Improvement via Feedback Loops

AI models in exploration are not one-and-done; they continuously improve as more data becomes available. This creates a feedback loop where initial predictions guide exploration, new data from that exploration (new drill holes, assays, surveys) are fed back into the model, and the model updates its predictions accordingly. Over the lifespan of a project—from early exploration to advanced resource drilling—the AI’s insights become progressively more accurate and refined. This iterative learning approach is analogous to how a human geologist’s understanding deepens with more information, but AI can assimilate the data faster and more quantitatively. The feedback loop ensures the exploration strategy adapts in near real time, always leveraging the latest knowledge to inform next steps, which leads to better outcomes than a static model or plan.

Mining AI platforms explicitly incorporate continuous learning cycles. For example, the firm VRIFY reports that as its client base grows and more drilling and assay data are added, their proprietary mineral exploration models “learn and refine their predictions,” becoming steadily smarter and more precise in targeting over time. In practice, one of VRIFY’s AI systems identified a gold mineralization zone at Southern Cross Gold’s project which aligned with the geologists’ independent interpretation; as further drilling was done, the AI model updated to reflect the new intercepts, honing the predicted shape of that zone with each iteration. This continuous improvement was integral to exploration planning: early-pass AI predictions were used to plan initial holes, and the results of those holes were immediately fed back to update the next set of predictions. Academic research mirrors this approach: “active learning” algorithms in exploration have demonstrated that choosing drill targets based on where model uncertainty is highest and then retraining on the new data can converge on an orebody model with fewer total holes. In short, the more data the AI receives, the better its models get—yielding a virtuous cycle wherein exploration becomes more efficient and accurate as it progresses.