Intermec has introduced the use of micro-electromechanical systems (MEMS) to supply chain data collection equipment. The use of MEMS-based technology offers the first major revolution in laser-based data collection in twenty years, making it possible to produce laser data collection scanners that are significantly faster, smaller, lighter, and more efficient than today's legacy scanners.

Millions of MEMS-based devices are already at work around the world. The use of MEMS in supply chain applications promises similar behind-the-scenes improvement to a company's supply chain operations. Because MEMS-based laser scanners are able to read bar codes up to 40 times as fast as today's legacy equipment, workers are able to capture information more rapidly and efficiently, speeding the flow of information through a supply chain and improving supply chain visibility.

"Advances in MEMS already enable us to sense and measure acceleration, acidity, temperature, pressure, stress and many other factors," indicates Gartner.

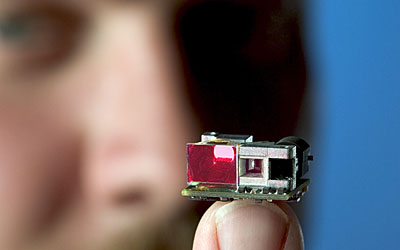

The first MEMS-based laser scan engine to be released, the Intermec EL10, features extremely fast scan rates and separate laser emission and collection optics for increased sensitivity, supporting increased scan range and angle, as well as easier scanning of low contrast bar codes. The miniaturization and solid state properties of the EL10's MEMS technology leads to greater durability and lower equipment failure rates.

The EL10 can operate at 500 scans per second, with the potential to go to 4000 scans per second, compared to standard laser scan rates of less than 50 scans per second. Its micro-mirror and associated drive motor are 1/66 the size of the mirrors used in traditional laser scanner designs, adding to its durability and compact size. The new MEMS-based scanning technology allows laser scanners to read more sophisticated types of bar codes, such as stacked and linear codes.