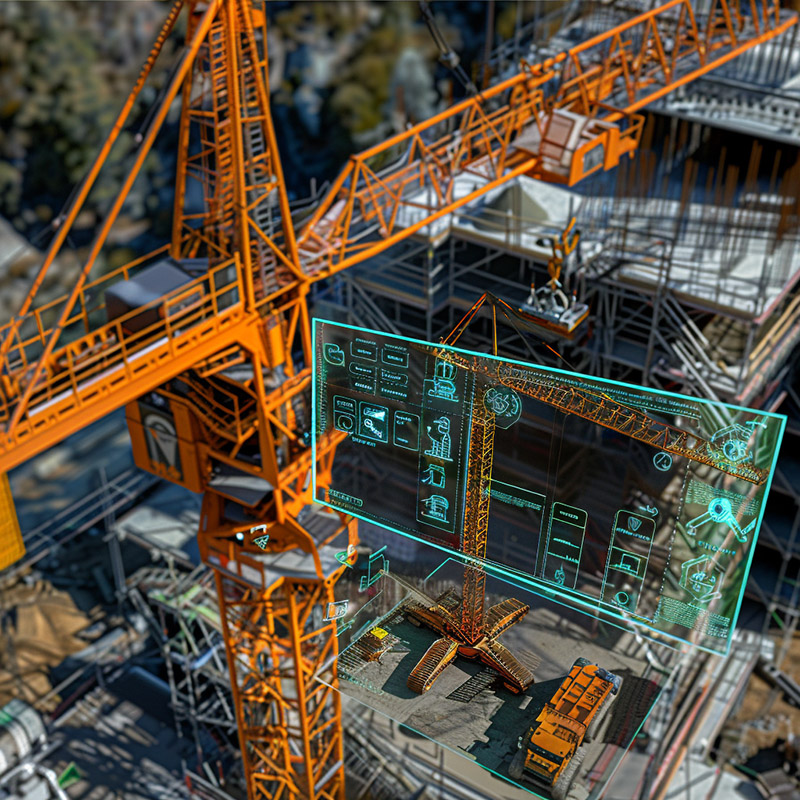

1. Project Planning Optimization

AI can analyze historical data and current project parameters to optimize schedules and resource allocation, predicting potential delays and recommending adjustments. This leads to more accurate planning, reduced timelines, and minimized risk of overruns.

Project Planning Before AI

Project planning in construction was often a manual process, reliant on the experience and intuition of project managers. This method could lead to inefficiencies, underutilization of resources, and frequent project delays due to unforeseen issues, resulting in increased costs and extended timelines.

Project Planning After AI

With AI-driven project planning optimization, construction schedules and resource allocation are dynamically adjusted based on real-time data analysis. AI algorithms can predict potential delays and automatically reconfigure schedules and resources to mitigate impacts, significantly improving project efficiency and reducing the likelihood of overruns. This leads to more accurate planning, optimal resource use, and timely project completion.

2. Automated Design Analysis

AI tools can swiftly evaluate design proposals against a vast array of criteria, including regulatory compliance, sustainability, and efficiency. This accelerates the design phase, ensures compliance, and enhances the overall quality of the construction plans.

Design Analysis Before AI

The design analysis process required significant manual effort to ensure compliance with regulations, efficiency, and sustainability standards. This often resulted in lengthy review cycles and potential rework if designs did not meet all criteria, delaying project progress.

Design Analysis After AI

AI-powered automated design analysis can instantly evaluate designs against a comprehensive set of criteria, identifying compliance issues, efficiency improvements, and sustainability enhancements. This accelerates the design phase, reduces the need for rework, and ensures that projects meet high-quality standards from the outset, streamlining the design-to-construction pipeline.

3. Real-time Resource Management

By tracking the real-time status of materials, equipment, and labor, AI systems can optimize the use of resources, reducing waste and ensuring projects stay within budget.

Resource Management Before AI

Managing resources on construction sites was a complex task, often leading to either shortages or surpluses of materials and labor, which could delay projects and increase costs. Resource management was reactive, with adjustments made after issues arose.

Resource Management After AI

With AI in real-time resource management, construction projects benefit from continuous monitoring and optimization of materials, equipment, and labor. AI predicts and responds to project needs, adjusting resource allocation on the fly to prevent shortages and reduce waste. This proactive approach ensures projects stay on schedule and within budget, significantly improving operational efficiency.

4. Predictive Maintenance of Equipment

AI algorithms can predict equipment failures before they happen by analyzing data trends, allowing for preventive maintenance that minimizes downtime and extends the lifespan of machinery.

Equipment Maintenance Before AI

Maintenance of construction equipment was typically scheduled at regular intervals or performed reactively in response to breakdowns. This approach could lead to unexpected downtime, delaying projects and increasing costs.

Equipment Maintenance After AI

AI-driven predictive maintenance analyzes equipment data to forecast potential failures before they occur, scheduling preventative maintenance to avoid downtime. This ensures equipment reliability, reduces repair costs, and minimizes project delays, enhancing overall productivity and extending the lifespan of machinery.

5. Enhanced Safety Monitoring

AI-powered surveillance systems can monitor construction sites for safety hazards, automatically identifying unsafe behaviors or conditions and alerting management, significantly reducing the risk of accidents.

Safety Monitoring Before AI

Safety monitoring on construction sites relied heavily on manual inspections and worker vigilance. Despite best efforts, accidents and unsafe conditions could still occur, posing risks to worker safety and project timelines.

Safety Monitoring After AI

AI-enhanced safety monitoring systems automatically detect unsafe behaviors and conditions using surveillance cameras and sensors, issuing real-time alerts to prevent accidents. This continuous, automated monitoring significantly reduces the risk of workplace incidents, ensuring a safer construction environment and compliance with safety regulations.

6. Quality Control Automation

AI can automate the inspection process, using drones and image recognition to monitor work quality, identify defects, and ensure that construction meets specified standards throughout every project phase.

Quality Control Before AI

Quality control in construction was a manual, time-consuming process that could miss defects or inconsistencies, potentially affecting the integrity of the finished project and leading to costly rework.

Quality Control After AI

Automated quality control via AI and drones enables continuous, comprehensive monitoring of construction quality, identifying defects or deviations from plans early in the process. This allows for immediate corrections, ensuring projects meet quality standards consistently, reducing rework, and maintaining project schedules.

7. Supply Chain Optimization

AI can predict material needs, track inventory levels, and optimize supply chain logistics, ensuring materials are delivered just in time, reducing holding costs, and avoiding delays.

Supply Chain Management Before AI

Supply chain management in construction was often reactive and inefficient, with material shortages and delays common, impacting project timelines and budgets.

Supply Chain Management After AI

AI optimizes the construction supply chain by predicting material needs, tracking inventory, and optimizing delivery schedules, ensuring materials are available when needed. This reduces storage costs, minimizes delays, and improves project efficiency, leading to smoother project execution.

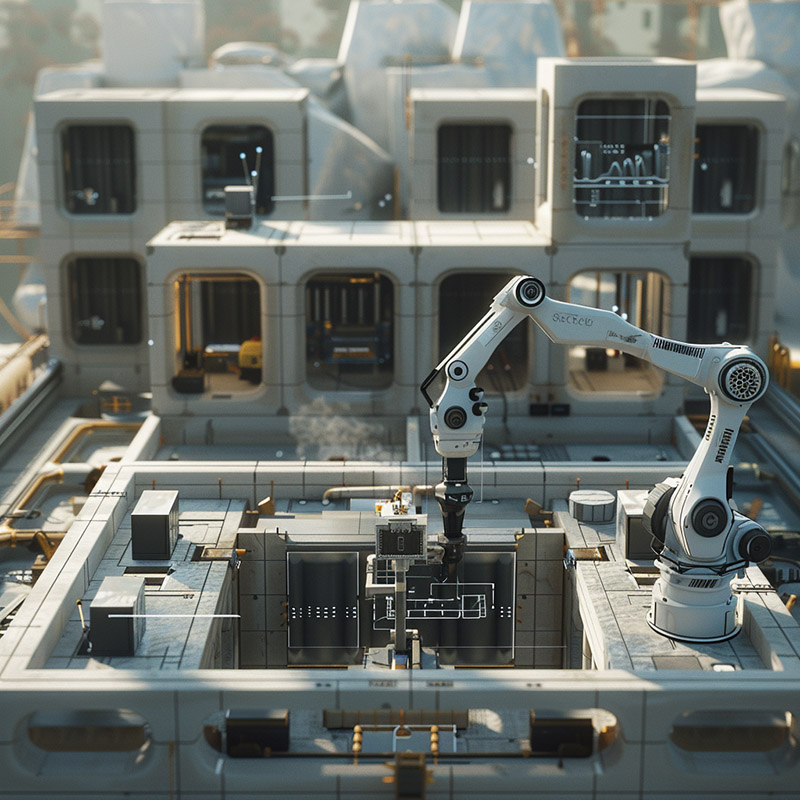

8. 3D Printing and Modular Construction

AI facilitates the efficient use of 3D printing and modular construction techniques, analyzing the best methods for prefabrication and assembly, reducing construction time, and lowering costs.

Construction Methods Before AI

Traditional construction methods were labor-intensive and time-consuming. The adoption of 3D printing and modular construction techniques was limited by the complexity of integrating these technologies into existing workflows.

Construction Methods After AI

AI facilitates the efficient use of 3D printing and modular construction, analyzing optimal designs for prefabrication and automating the assembly process. This reduces construction time, labor costs, and material waste, while also improving safety and quality, revolutionizing how buildings are constructed.

9. Data-Driven Decision Making

With AI, construction managers can access insights derived from big data analytics to make informed decisions regarding project direction, financial planning, and risk management, enhancing strategic planning and operational efficiency.

Decision Making Before AI

Decision-making in construction projects often relied on limited data and personal experience, which could lead to suboptimal outcomes and increased risks.

Decision Making After AI

AI-driven data analytics provides comprehensive insights into every aspect of a construction project, from cost forecasts to risk analysis. This enables informed decision-making, reducing uncertainties and optimizing project outcomes. Managers can now rely on data-driven insights to guide strategic planning and operational decisions, enhancing project success rates.

10. Labor and Productivity Analysis

AI systems can analyze worker productivity and identify bottlenecks in construction processes, suggesting improvements and training needs to optimize labor use and increase project efficiency.

Worker Productivity Before AI

Analyzing worker productivity and identifying process bottlenecks were challenging, often leading to inefficiencies and extended project timelines without clear solutions.

Worker Productivity After AI

AI systems analyze labor productivity and identify bottlenecks in construction processes, offering actionable insights for improvement. This enables targeted interventions, such as reallocating resources or providing additional training, to optimize workforce efficiency and enhance overall project productivity.