EMI shielding gaskets serve an important purpose in blocking electromagnetic interference (EMI) in electronic devices and systems. Here are some key points about EMI shielding gaskets:

- Purpose - EMI gaskets prevent electromagnetic waves from entering or escaping an enclosure or joint in electronic equipment. This interference can disrupt signals and cause malfunctions.

- Materials - Typically made of conductive materials like metal, conductive elastomers, conductive fabrics or foams. This allows electrical connectivity to block EMI.

- Locations - Used in any shielded enclosure joint or seam such as doors, access panels, windows, vents, or anywhere two metal surfaces meet. Also used around connectors and ports.

- Function - When compressed between two surfaces, the conductive gasket material shorts the tiny gap to electromagnetic waves. This forms an effective barrier preventing interference transmission.

- Performance - Good shielding effectiveness over a wide range of frequencies. Measured in decibels of attenuation. High level of contact conductance for electrical connectivity.

- Designs - Variety of gasket profiles available like o-ring, d-profile, tongue-and-groove, or spring-finger to suit application. Can be custom designed.

- Compliance Standards - Help electronic products meet EMI/EMC, FCC, CE marking requirements for emissions and immunity.

EMI gaskets block disruptive electromagnetic noise, preventing interference issues and allowing proper functioning of sensitive electronic systems and components. Their careful selection and optimal placement are critical in EMI control.

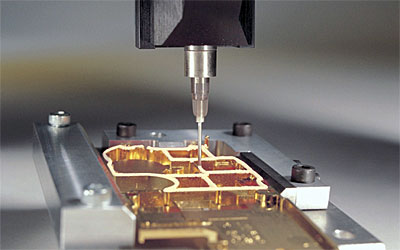

Form-in-place system dispenses conductive compounds onto intricate enclosures to provide a custom-applied shield

In 2006, Laird Technologies introduced its Hi-Strength SNL65HS Form-In-Place gaskets that are ideally suited for a broad range of applications where shielding, environmental protection and durability are key requirements.

The custom-designed system accurately dispenses conductive compounds onto intricate enclosures providing a custom-applied environmental and EMI shield. The high strength gasket is comprised of specially designed silicone with silver aluminum filler to complete the conductive elastomer in a cost-effective manner. This combination results in a durable and resilient gasket that offers excellent EMI shielding effectiveness and environmental security.

The unique compound is engineered to protect electronics from moisture, dust and other contaminants while providing a durable gasket that withstands component handling, assembly and frequent housing openings and closings thus extending the gasket and end-product's life.

Superior adhesion and gasket tear strength protect telecommunications infrastructure equipment applications such as power amplifiers, transceivers, wireless transceivers, and antenna housings. Handheld test and calibration equipment, automotive control modules, and high-power emergency radios are also improved.

Laird Technologies designs electromagnetic interference shielding.